About Us

Thanks for visiting. We’re a custom technical ceramic manufacturer delivering unique material and engineering solutions to a wide range of industries, including aerospace, defense, analytical instrumentation, energy, oil and gas, semiconductor, and more. We host over 135,000 square feet of manufacturing space in northern Vermont, and have earned numerous certifications, including ISO 9001:2015 and AS9100D certificates, along with ITAR registration, and REACH and RoHS compliance.

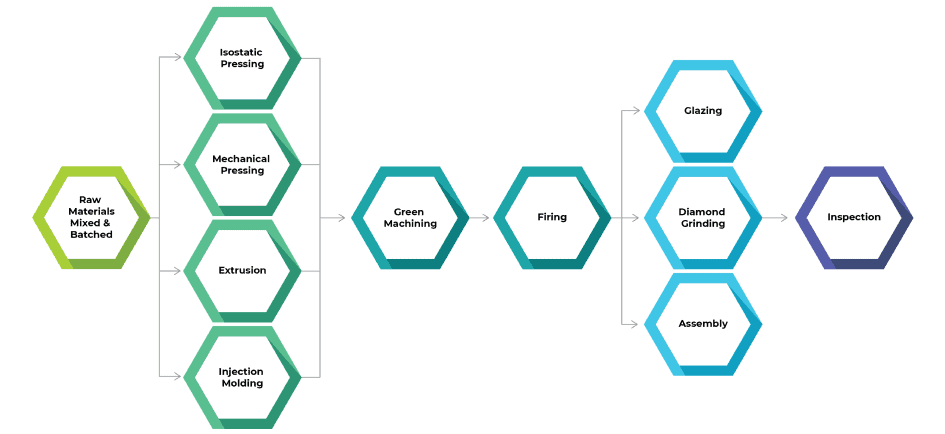

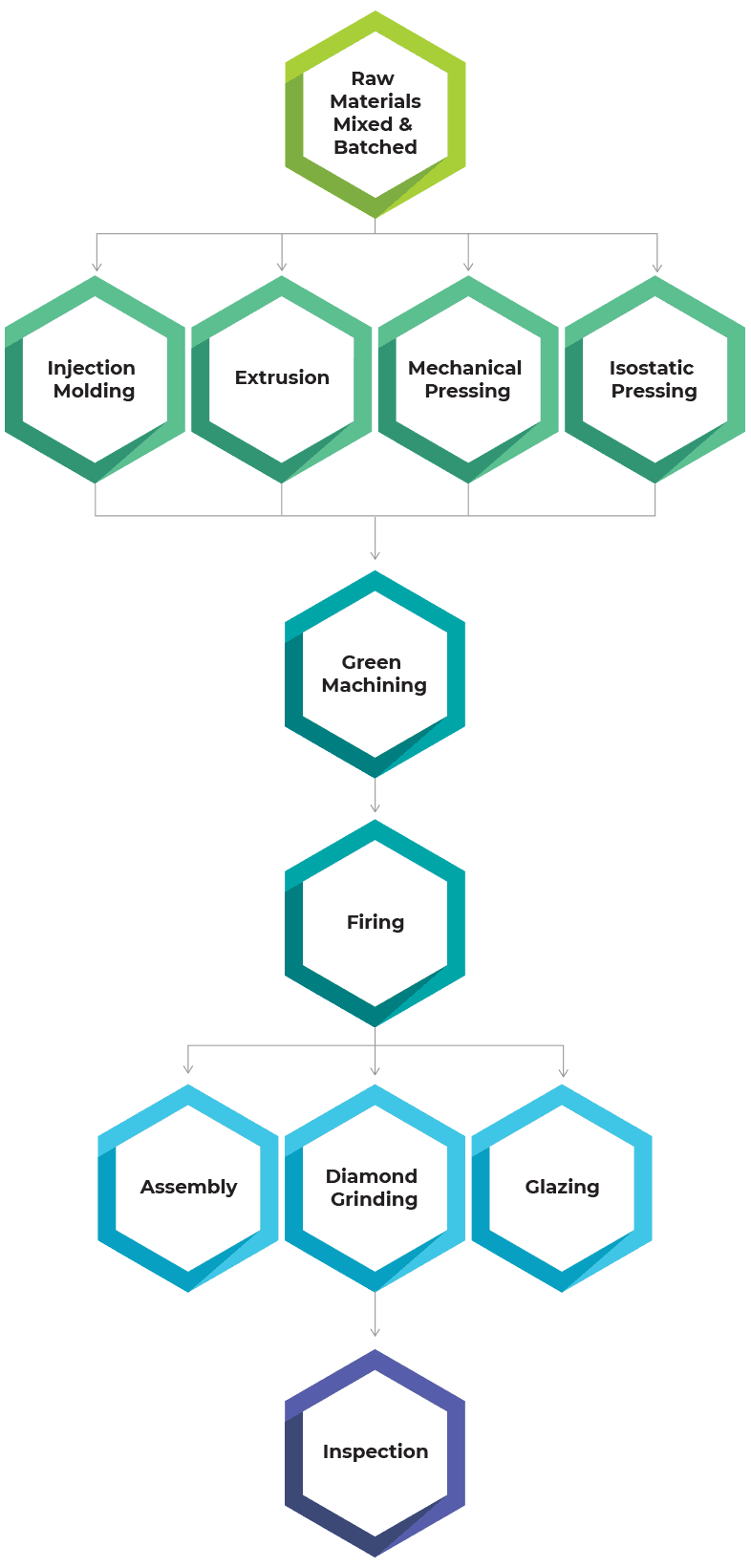

How We Work

We’re renowned for our ability to manage all aspects of the technical ceramics production process in-house, while maintaining high degrees of responsiveness to our customer’s needs. This is due to our tightly integrated company culture, coupled with the latest manufacturing equipment. Take a tour of some of our facilities, below.